Meurer film packaging: Modular systems – maximum transport safety

Film packaging from Meurer means you can transport single packages and even multipacks safely, economically and with absolute reliability. We know what your market calls for. For the beverage and food industry, we deliver the high-performance end-of-line packaging machines you need. With us, you benefit from comprehensive support from optimal development of packaging through project planning to implementation, and even beyond.

Our basic machines can be combined and modified with functional units in a modular system. Easy line integration is a given with all our machines. We can also upgrade and retrofit your machines at any time cost-effectively.

Meurer film packaging –

The benefits:

- Handle products with care

- Choose from individual product groupings

- Choose from tried-and-tested function modules

- Product-specific adjustments to pre-designed and tried-and-tested function units

- Various control/automation systems

- Connect to various external systems

- Maximum flexibility for different film types (stretch film, shrink film, stretchable and recyclable)

- Save on film with stretchable films

- Minimized energy consumption

- High system availability of up to 98%; solid process reliability

- Ergonomic and controls are easy to understand

- Intuitive control with touch panel

- The latest drive technology

- Fast, automated format changes

- Compact and space-saving design

- Low maintenance costs

- Easy to clean

Selected solutions

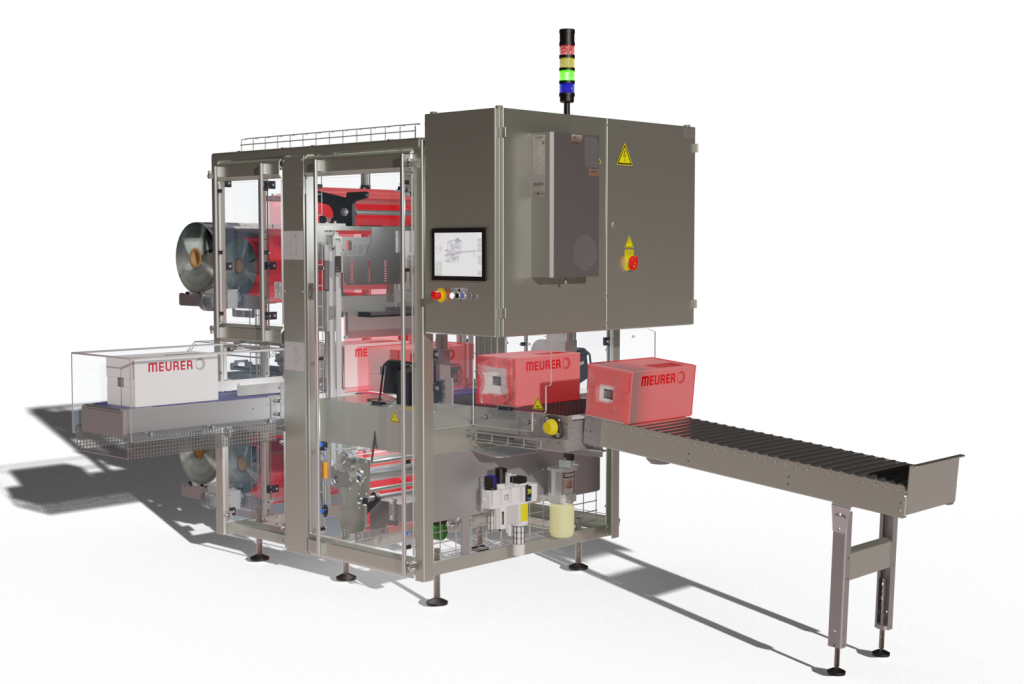

FL FILMLINE

- Packaging Performance up to 35 bundles/ Minute

- Machine Efficiency up to 99%

- Fast and easy format change

- Inline principle or side infeed

- For Trays or single packages

- Shrink and stretch film

- Edge shrinkage or shrink tunnel

- Welding tool Air and water cooled

- Small footprint

- Modular and robust construction made of stainless steel and rustproof material, suitable for wet cleaning

- Automation systems: Siemens, Rockwell, Schneider

- Extra: J-Board, Card-Inserter, Print mark control

HEM HIGH-SPEED WRAPPING MACHINE

- Packaging Performance up to 60 bundles/ Minute (as Tray Shrinker)

In two-lane version up to 80 packs/minute (multipacks)

- Machine Efficiency up to 99%

- Inline principle or side infeed

- Single or double lane design

- High degree of format flexibility: one- to three-row packs

- Semi-automatic film roll change, optional: fully automatic

- Modular and robust construction made of stainless steel and rustproof material, suitable for wet cleaning

- Automation systems: Siemens, Rockwell, Schneider

- Extra: J-Board, Card-Inserter, Print mark control

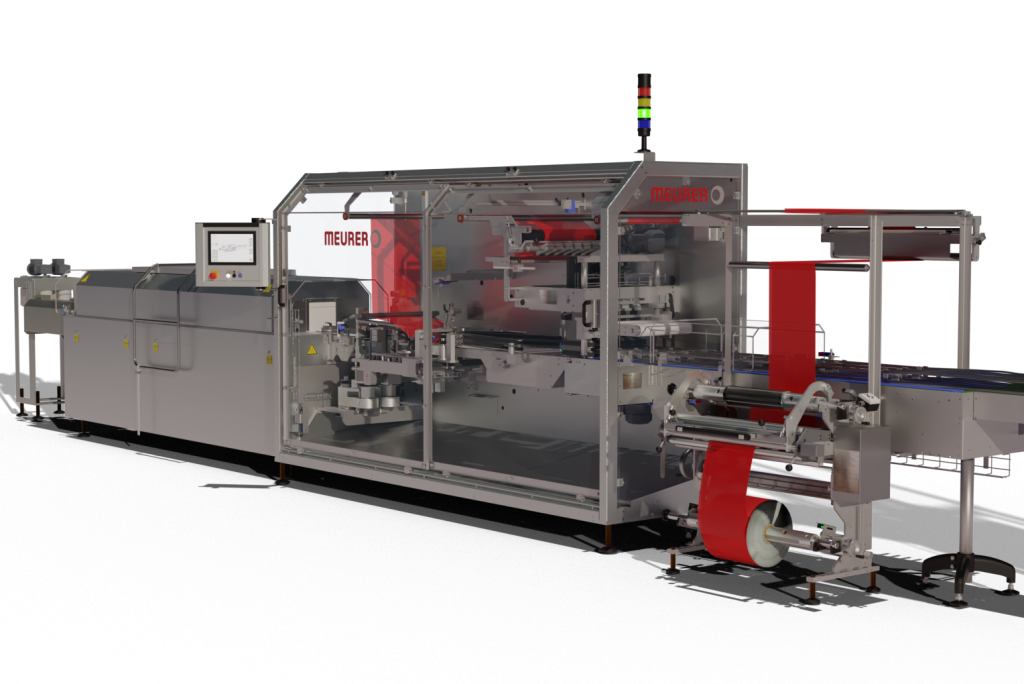

HHS HIGH-SPEED HORIZONTAL FLOW WRAPPING MACHINE

- Packaging Performance up to 160 bundles/ Minute

Processing of 28,000 packs/ hours

- Machine Efficiency up to 99%

- Fast and easy format change with few format parts

- High degree of format flexibility: one- to three-row packs

- Flow Wrap with shrink film

- Fully automatic product grouping

- Full wrap with shrink film

- Modular and robust construction made of stainless steel and rustproof material, suitable for wet cleaning

- Automation systems: Siemens, Rockwell, Schneider

- Extra: J-Board, Card-Inserter, Print mark control